Filling

Volumetric, mass-flow and gravimetric filling machines

Contents

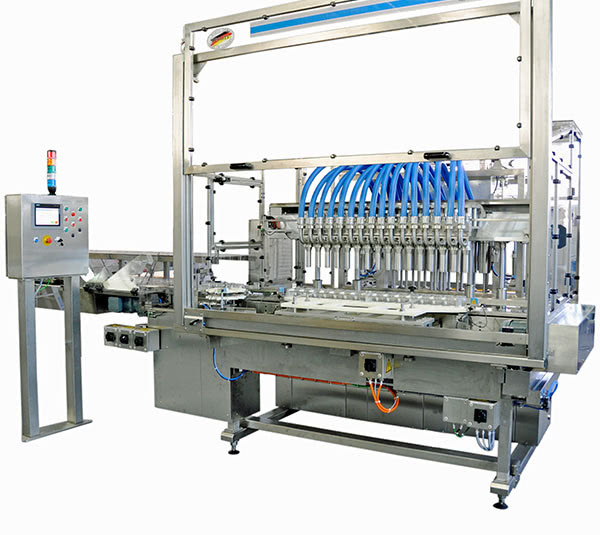

Mass-flow filling machine RFC

Dosing Filling Machines

General

- Volumetric, mass-flow and gravimetric filling machines

- 1-16 filling positions, linear and rotating, clocked

- Pharma, Food, Chemistry, Cosmetic, Special applications

- Filling range from ca. 1 ml up to 60.000 ml resp. g

- Strong foaming up to high viscosity liquids / pastes

- Filling in Cartridges, Bottles, Canisters and Special designed bottles made of plastic or glass

- GMP/cleanroom application possible

- ATEX application possible

- Applicable in the food section

- Different leading product materials: alloys 1.4301-1.4404-1.4571, HASTELLOY, titanium, tantalum, PP, PVC, Duran-glass, PTFE, ECTFE i.e.

Machine equipment for

- Solvents

- Toxic, Abrasive products

- Hot filling

- Sterile filling under LF

- ATEX products

- Adhesives, isocyanates

- Shear sensitive products

- Products with coated active ingredients (plant protection)

- Acids and alkalines

- Food

- Biocides

- Etc. ...

Volumetric

Type RF Servo

- CNC-controlled piston-filling-machine

- 2, 4, 6 up to 16 filling positions

- Dosing range 2-30.000 ml., dependent upon the dosing piston sizes

- CIP/SIP optional

- ATEX optional

- GMP optional

- Integrated cleaning programs

- Multi-colour filling as special design

- Dosing pistons/cylinders optional as rotary pistons ZIRKON

- Hot-filling optional

- Special design in HASTELLOY/Titanium

Mass-flow

Type RFC

- CNC-controlled mass-flow filling machine

- 2, 4, 6 up to 16 filling positions

- Dosing range 20-30.000 ml., dependent upon the dosing piston sizes

- Rapid and uncomplicated cleaning through integrated CIP

- Free vertical movement of the filling nozzles

- Automatic density balance

- Self-draining by open valves

- ATEX optional

- SIP optional

- GMP optional

- Multi-colour filling as special design

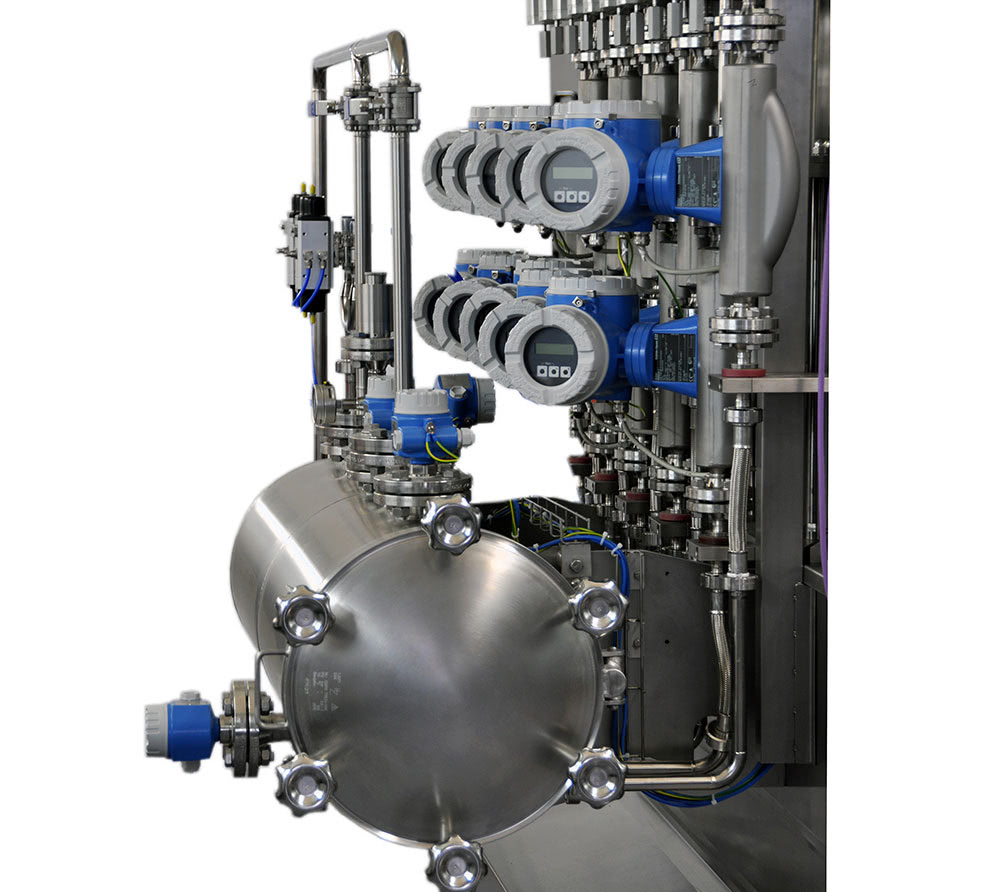

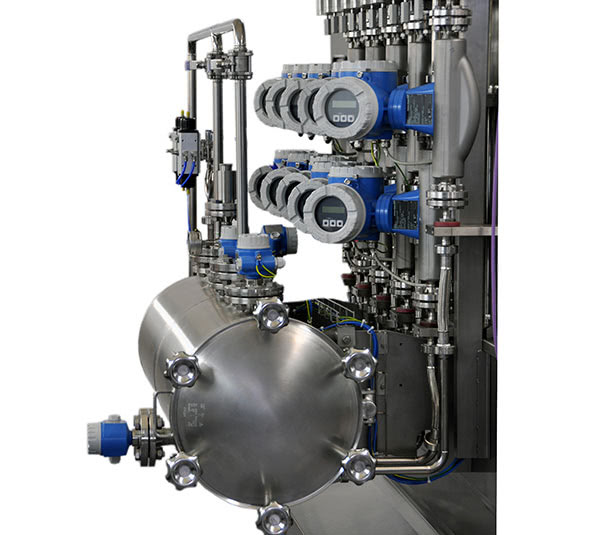

CNC-controlled mass-flow filling machine RFC 4+4-15* with capping machine GKV Servo Control

*Special design

CNC-controlled below-level filling & 2 separate filling systems, each with 4 filling nozzles and 1 pressure tank each

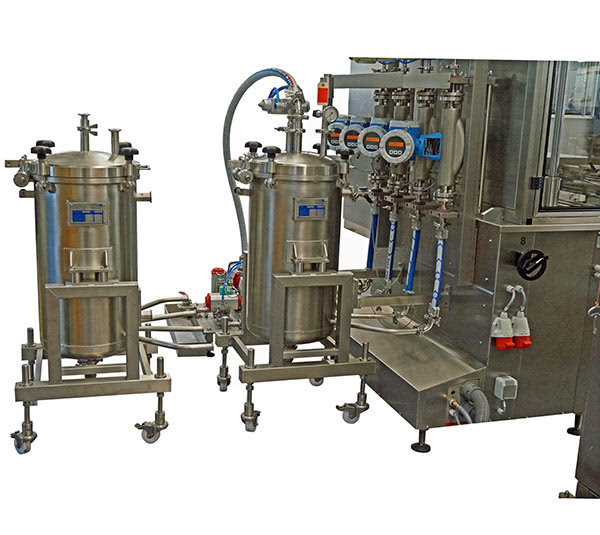

RFC 10-15 rear-filling machine

Pressure tank with automatic control of differential pressure control & integrated CIP-system

Gravimetric

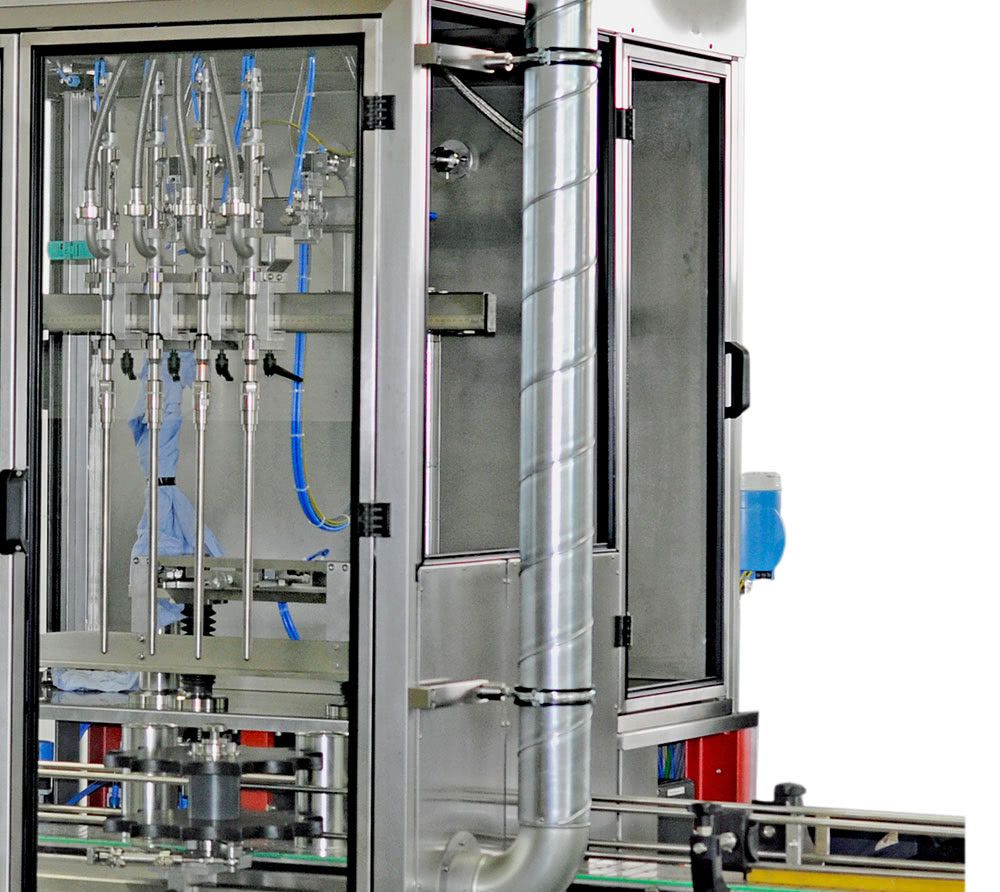

WFM 2-50 CNC-controlled gravimetric Filling machine

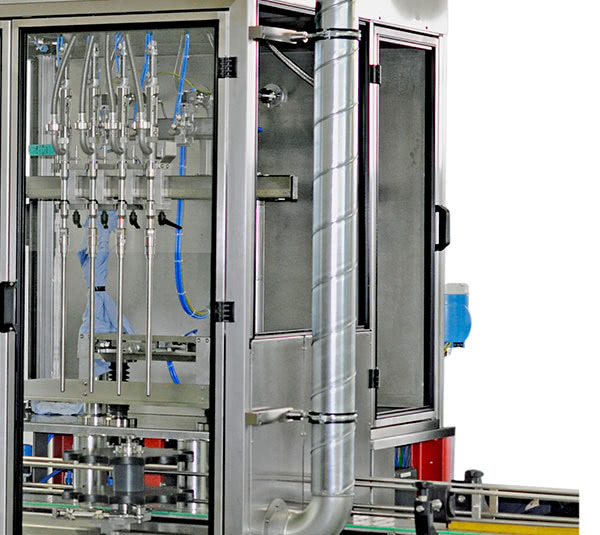

CNC-controlled below-level filling; integrated CIP

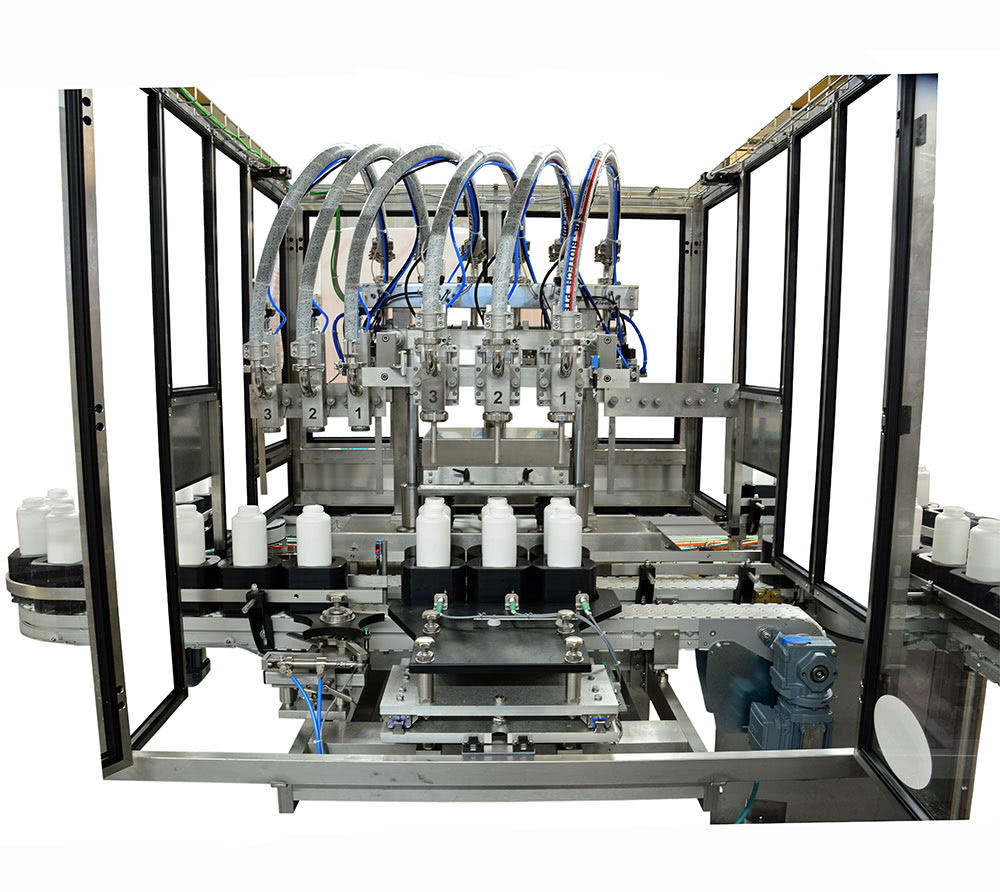

WFM 2-50 CNC-controlled gravimetric Filling machine

Automatic separation and positioning of the bottles, format-free

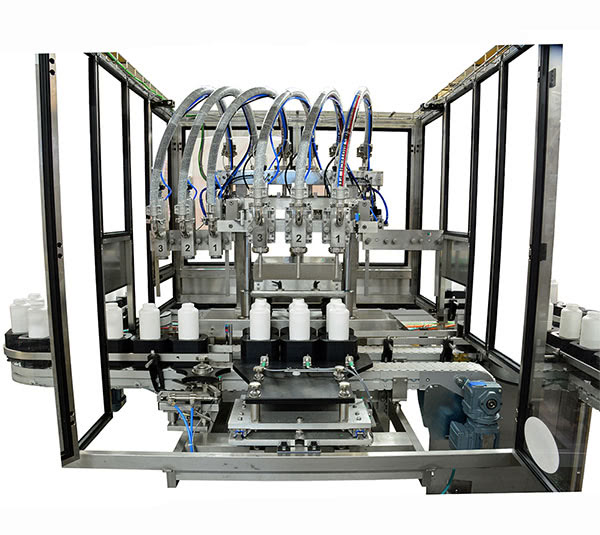

WFM 2-50 (machine inside)

format-free, servo-controlled Bottle separation and positioning; tool-free format change

CNC-controlled, 4-digit gravimetric Filling machine WFM 5-1000

ATEX Design & integrated 4-digit N2-Nitrogen

2-digit, semi-automatic gravimetric Filling machine WFM 2-1000

Semi-automatic closure station & integrated N2 Nitrogen injection

Type WFM

- CNC-controlled gravimetric Filling machine

- Max. 4 filling positions

- Weighing range max. 30 kg

- Calibratable design optional

- Clocked or as in-line filling machine

- ATEX optional

- GMP optional

- CIP/SIP optional

- Special design in HASTELLOY/Titanium

Filling and Capping Machine

Type RTM

Multifunctional in limited space and utmost flexibility through consistent CNC technology

Application:

- Small batch sizes

- Multiple-parts Closure Systems

- The modular construction of the RTM allows for the application of different Dosing and Closure Systems

- CNC-controlled Rotary-clocked Filling and Capping machines

- Optional filling through 1- or 2-digit Piston-Dosing with servo drive, Rotary Piston-Dosing with separate servo drives, mass-flow measuring or weighing elements

- Capping option with either, 1 or 2 digit capping stations with mechanical torque speed limitation or with servo driven torque speed limitation and positioning capability

Equipment

Optional

- LF preparation

- Calibratable design (WFM)

- CIP/SIP equipment for Pharma and Food

- Hot-filling

- Multi-component filling

- Changeable filling systems, Duo-design

- Nitrogen injection possible

Special design

- ATEX

- GMP

- Pharma-line

- Acid-/Alkaline equipment

Our depth of manufacture

- Construction

- Conventional + CNC machining

- Complete engineering

- Welding in different classifications

- Switch cabinet construction, PLC programming